This course is available in-company. Please contact us for details.

Course overview

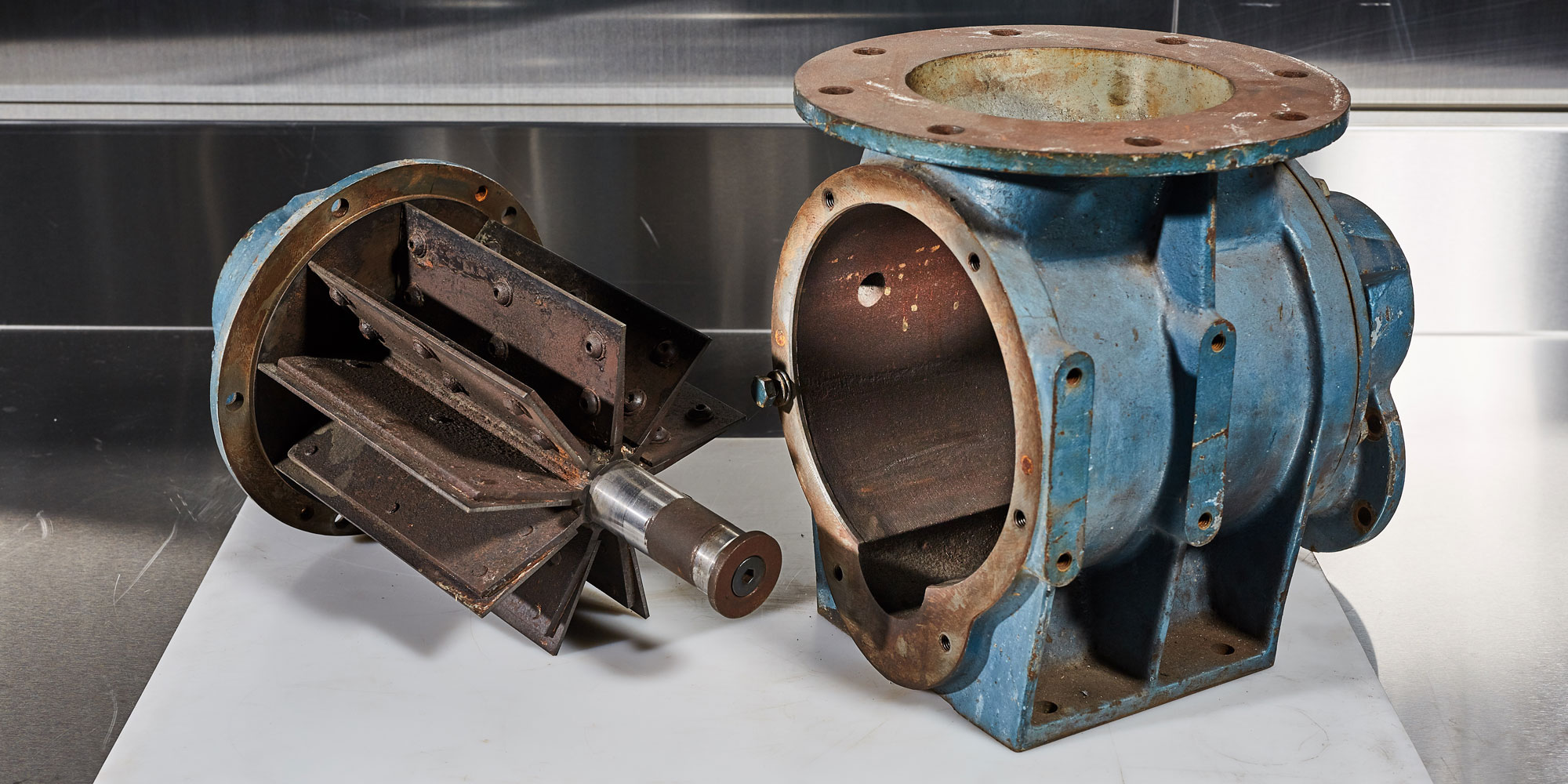

Rotary valves are widely used to feed pneumatic conveying pipelines, and for feed metering, explosion isolation, atmospheric isolation etc. However there are literally thousands of combinations of different feature options available covering choice of materials of construction, rotor type, drive type, venting arrangements, bearing pattern, seal choice, clearances, cleaning features etc. Faced with this bewildering choice, how does an engineer decide what to specify? This course will help understand the reasons for the different options and how to choose them.

Format

This course concentrates on the practical aspects of technology.

Subjects covered

Topics will include:-

- Application areas for rotary valves, and their different demands (feeding, explosion protection, isolation etc)

- Basics of rotary valve performance – air leakage, feed rate etc

- Materials of construction linked to issues of wear and build-up

- Seals and bearings, options, functions and selection

- Special consideration for explosion isolation

- ATEX requirements and responsibilities

- Features for cleaning and preventing contamination

- Venting – needs, options and ensuring success

- Review of practical application issues

Case studies of failures and successes will be used to demonstrate the importance of correct specification.

Is it for me?

The course is aimed at engineers, system designers, maintenance personnel who have responsibility for sourcing, specifying and keeping operational rotary valves in all industries.

Venue

The course will take place at the University of Greenwich Medway campus in Kent ME4 4TB

Course Team

The course leader is Mike Bradley, Professor of Bulk and Particulate Technologies and Director of The Wolfson Centre. He has worked internationally on design and troubleshooting of bulk solids handling as a commercial consultant and research expert for over twenty years.

Also contributing will be

Dr Baldeep Kaur, whose interests lie in characterisation and transportation of bulk materials;

Dr Vivek Garg, whose interests lie in powder flowability;

Dr Atul Sharma, whose interests lie in pneumatic conveying systems.

Please note that The Wolfson Centre reserves the right to substitute leaders of equal quality should this be dictated by circumstances beyond their control.

In-Company course

This course can be delivered as an In-Company course. These are proving to be a popular option for companies who have a number of personnel who would benefit from education in the subject area, for 3 main reasons:

- Cost: It is more economic for us to bring the course to you, than for you to send several staff out to us;

- Relevance: We can tailor the course programme to suit the operations you have in your plant, hence reducing the amount of material which is not directly relevant;

- Convenience: We can run the course when it suits you, even over several separate days rather than in a block if it is better for you.

If you are interested in discussing your requirements, please contact us.